Niscco Technical Center

NISCCO TECHNICAL CENTER

Technical Center of Splice Sleeve Japan, Ltd. with the highest grade equipment among rebar splice manufacturers

In March 2014, the research facility Nissco Technical Center, of the grout-filled rebar splice pioneer, Splice Sleeve Japan, Ltd. moved its location to Matsudo, Chiba Prefecture, and began further enhancing its facilities. Today, this a research center is one of the leading facilities in Japan, . It is equipped with a large-scale structural testing loading frame machine and two large-scale fatigue test machines, which are unmatched by any rebar coupler company.

As a result, various experiments required for product development can be carried out more quickly, and products that meet customer needs can be quickly supplied.

"We want to make the best rebar splices"- , Nissco Technical Center that splices all the employees' spirits is introducing the latest NMB Splice Sleeve System to the world.

Splicing spirits, splicing trust and splicing to the future

| Machine | Capacity(kN) | Make |

|---|---|---|

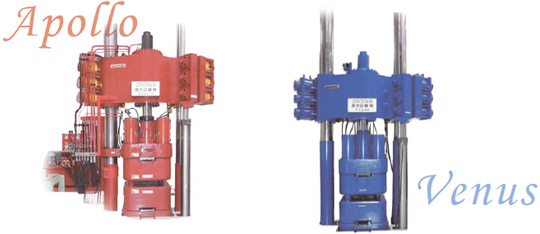

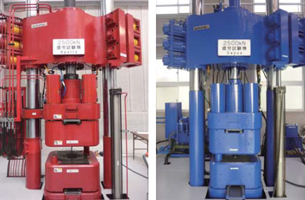

| 2500 kN Fatigue Testing Machine (Apollo) | 2500 | AutoMax |

| 2500 kN Fatigue Testing Machine (Venus) | 2500 | AutoMax |

| 2000kN Amsler Universal Testing Machine | 2000 | Shimazu |

| 1000kN Automatic Compressive Strength Test Machine | 1000 | Marui |

| 1000kN Compressive Strength Test Machine | 1000 | Giken |

| Ohno-type Asymmetric Loading Machine | 1000 | Oxjack |

The power for the future will be created from the most fulfilling equipment in Japan

2500kN Fatigue Testing Machine (Apollo and Venus)

Computer-controlled testing machines applicable for the test requirements stipulated in the rebar splice standards of Japan as well as other countries around the world. Two machines enable us to conduct tests more frequently.

2000kN Amsler Universal Testing Machine

For compressive strength test of grout collected on site and ultra-high strength grout test under development

1000kN Compressive Strength Test Machine

(Automatic and Manual Operation)

For testing ultra-high strength grout and concrete.

Ohno-type Asymmetric Loading Machine

A device for conducting structural tests of columns and beams. We are the first rebar manufacturer equipped with the machine in Japan.

Temperature/Moisture Controlled Rooms

By having two rooms, tests of 20℃ standard conditions and tests that simulate the construction conditions in summer or winter can be performed at the same time.